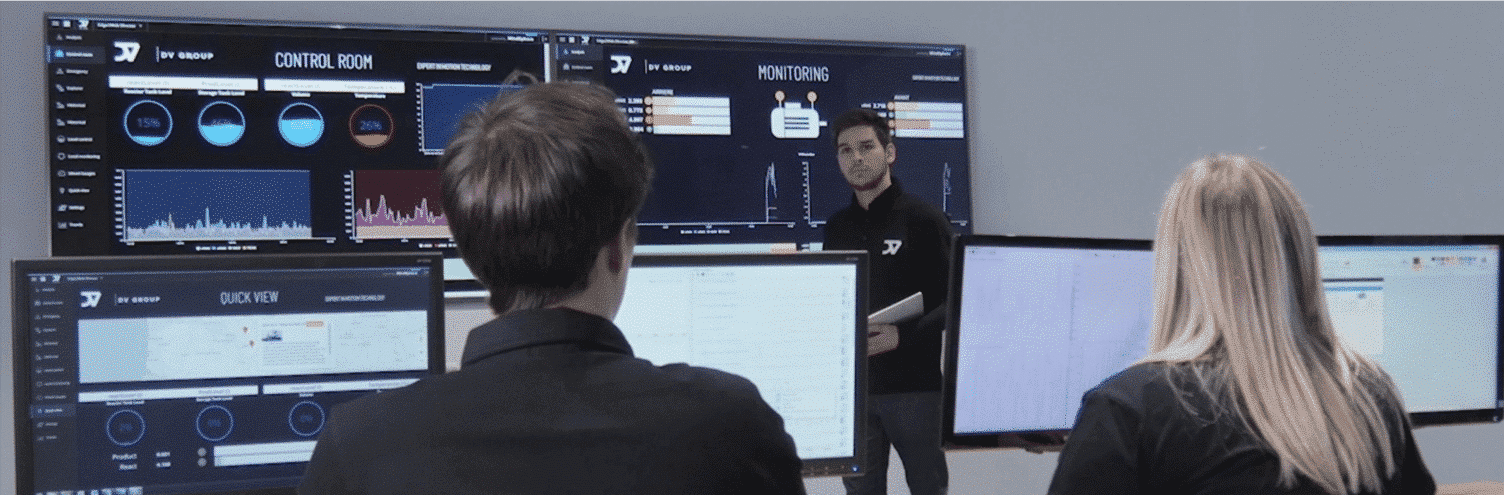

Reduce and understand your energy consumption with SMART ENERGY

Case studies

11 April 2024

DV News

News

Case studies

Following the Covid-19 pandemic we’ve been suffering for several months, some key concepts such as intelligent machines and factories, cyber-physical systems (CPS), the cloud and data analysis etc. are proving to be a precious aid in the unprecedented situation we are experiencing.

Get out white book free of charge in just a few clicks.

More

We tell you all about it in this 28-page white paper.

Get out white book free of charge in just a few clicks.

More