Our expertise

Maintenance

Electronical Maintenance

Our specialities is repair solutions dedicated to powerful electronics,

the mastery of electronic techniques and the use of adapted tools.

Procedures

- Nominal load testing, dynamic testing, loop position application, speed and torque scale

- Test programme, cycle times, part programme, system parameters, memory, E/S condition counter-measurement, test in communication with the robot, CN or monitoring

- Robot trajectory testing, communications and connectivity

Our ranges processed

AC/CC DRIVE: COMPACT DRIVE – LARGE DRIVE (POWER DRIVE)

SIEMENS : Micromaster, Simovert, Simoreg…

SCHNEIDER ELECTRIC : (Telemecanics) Altivar, Rectivar…

LEROY SOMER Control Techniques :(CAP) Unidrive, Digidrive…

ABB : ACS800, ACS 4000, ACS5000, ACS6000, DCS500B…

DANFOSS : VLT2000, VLT3000, VLT5000, VLT6000…

LENZE : EVF8000…

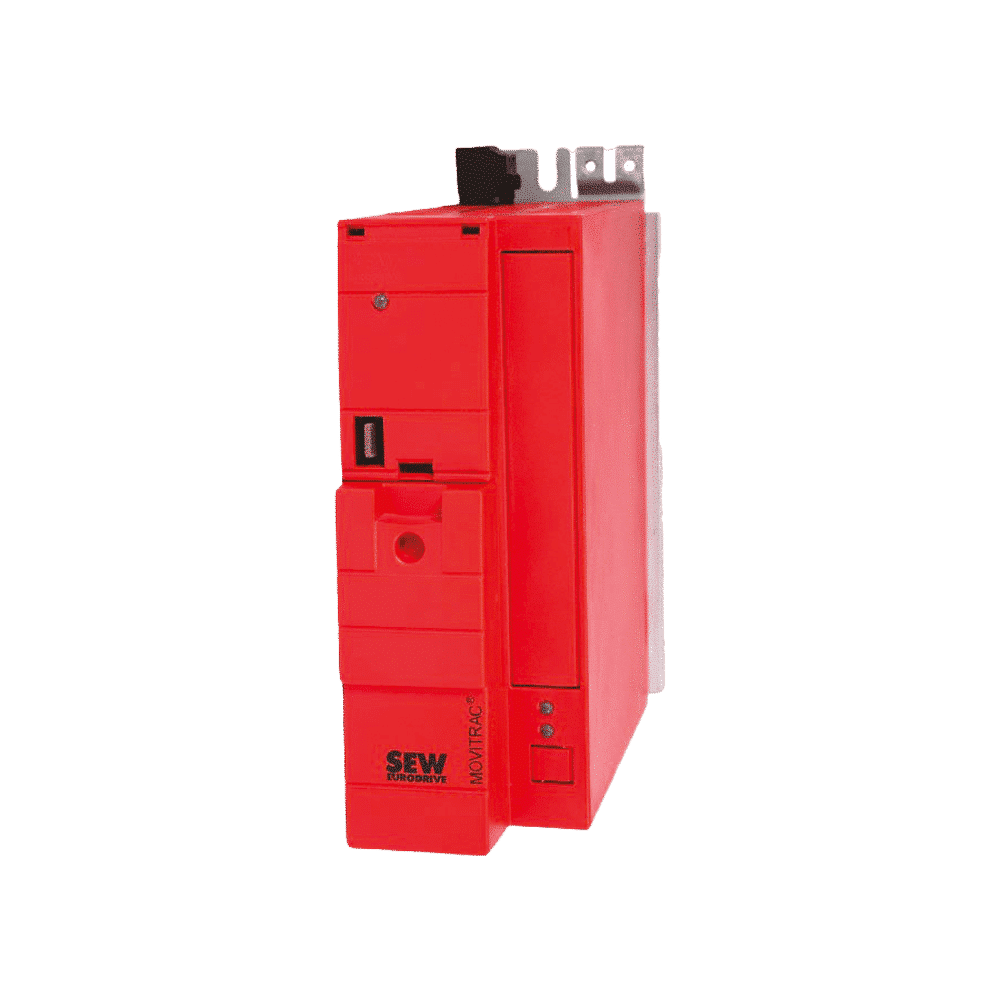

SEW : Movitrac, Movidrive…

ALLEN BRADLEY : UltraFlex, PowerFlex…

KEB : Combivert…

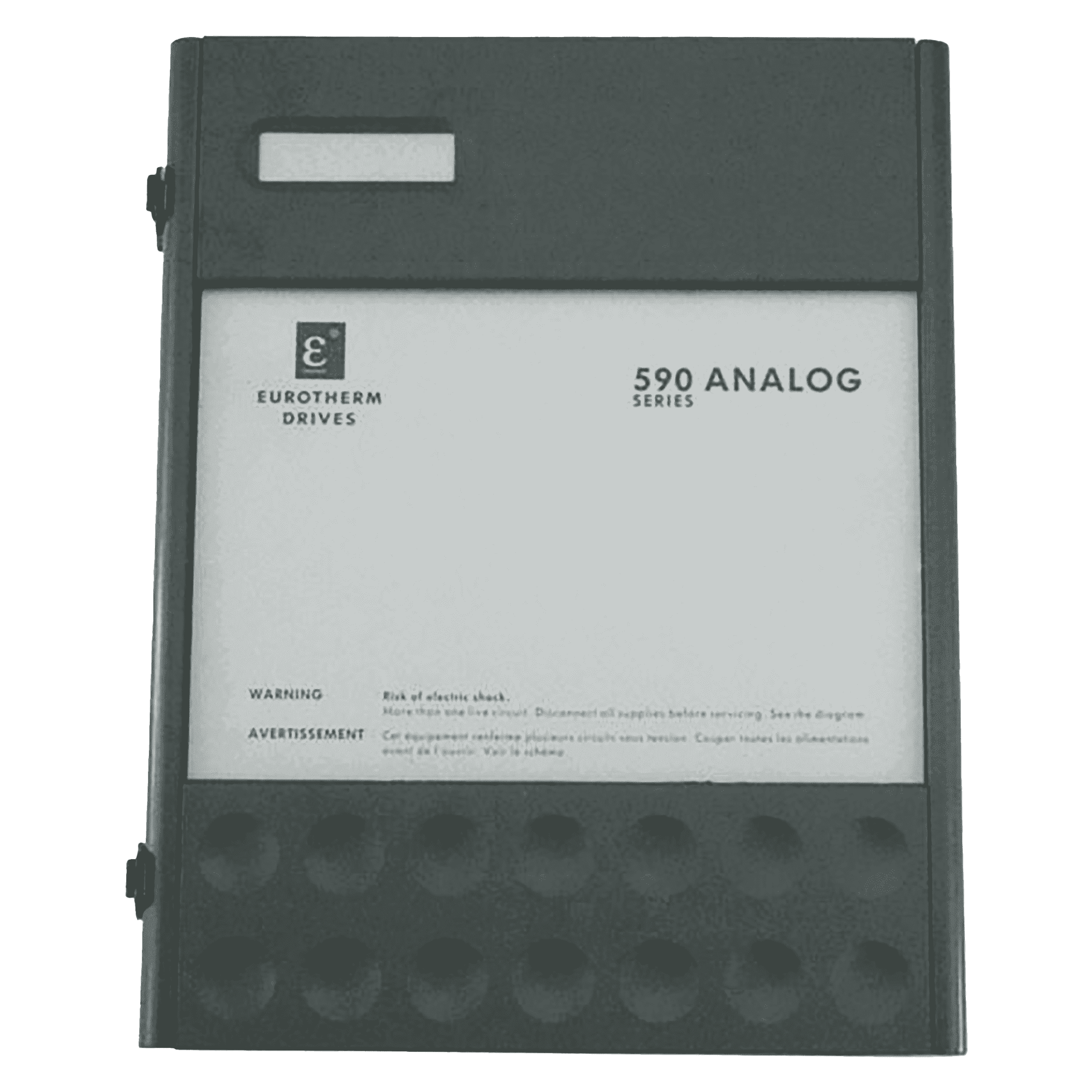

EUROTHERM : 584, 590, 605, 650…

LEROY SOMER : Powerdrive…

SIEMENS : Masterdrive, Sinamics…

ABB : ACS800…

DANFOSS : VLT5000, VLT6000…

HMI & PLC

SIEMENS : Simatic S5 : 95 / 100 /115 / 135 / 155 U… Simatic S7 : 200, 300, 400…

SCHNEIDER ELECTRIC : (Telemecanics) TSX 17, TSX 47, TSX 37, TSX 57…

ALLEN BRADLEY : SLC 500, Control Logix…

OMRON : CPU 21, CQM 1…

DIGITAL CONTROL / AXIS DRIVER

SIEMENS : System 3, 810, 820, 850, 880, 840C, 810C, 840D, 840DSL…

FANUC Séries 0, 6, 15, ALPHA (16. 18. 21…) ALPHAI (16i, 18i, 21i…)

NUM : 720, 750, 760, 1050, 1060…

SIEMENS : Simodrive 610, Simodrive 611, Sinamics S120, Sinamics S110…

FANUC : Série 0, 6, Alpha, Alphai…

SCHNEIDER ELECTRIC (TELEMECHANICS) : Lexium…

LENZE : EVS93, EVP93…

ALLEN BRADLEY : 1391, 1394…

BOSCH/INDRAMAT : DDS, DKC, DKR, DKS, DSC, HDS, KDS, KDA, TDA, KDV, KDW, TDM, RAC, BZM, TVD, HMV, KVR, TVR, TVM, NAM, REFU 316, REFU RD51…

ROBOTS

KUKA : KRC1, KRC2, KRC4

ABB : S4C, S4C+, IRC5

FANUC : R-J3

Onsite service

- Diagnostics

- Maintenance call-outs

- Modification, regulation adjustment

- Expert examination of breakdown reoccurrence

- Expert examination of fault origin

- Preventive action