Obsolescence Management: Audit of a Truck Engine Factory’s Equipment Fleet

Case studies

14 November 2023

Our expertise

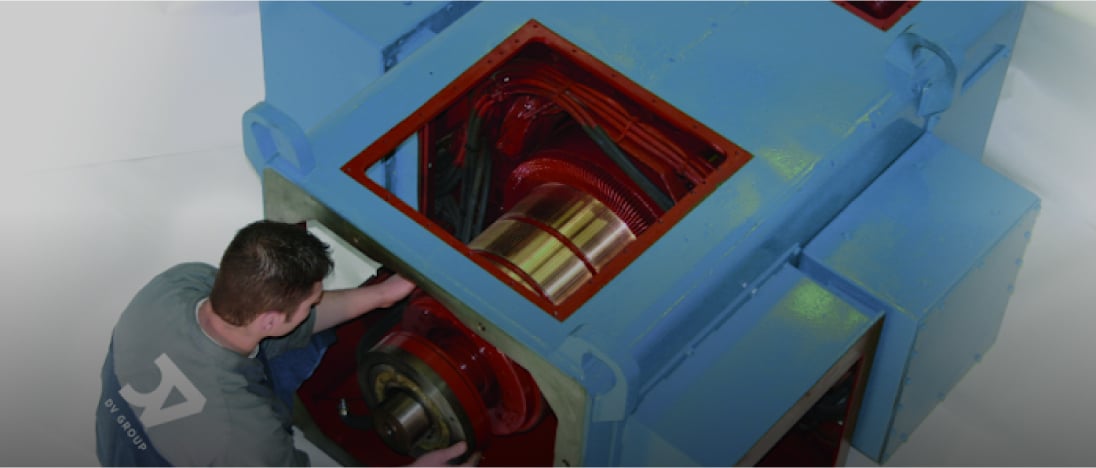

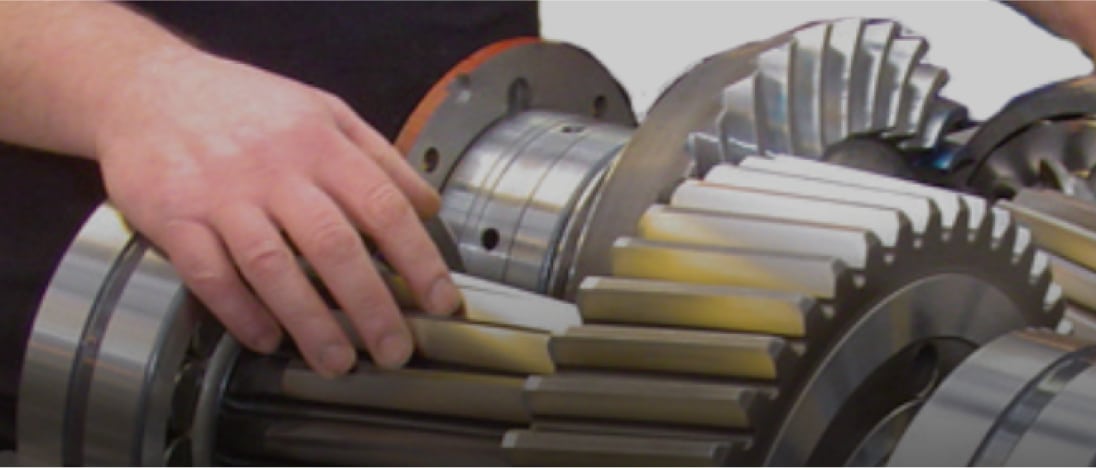

Ensuring the availability and increasing the reliability of your AC/DC motors and your elements,

such as reducers, pumps, ventilators etc.

Solutions

Solutions

Solutions

Solutions

Solutions

Solutions