Our expertise

Engineering

The success of an industrial project lies in the accurate identification of the risks and the efficient management of the study, implementation, development and support phases during which we offer you our support.

We carry out all our projects in collaborative mode via our MyDVConnect platform.

Engineering

Integration

Imagine – Innovate – Transform

We industrialise processes implementing methods (electrical designs according to optimum standards and sizing), skills, technical impetus and quality. We guarantee performance and support you with integrated solutions including piloting and trials.

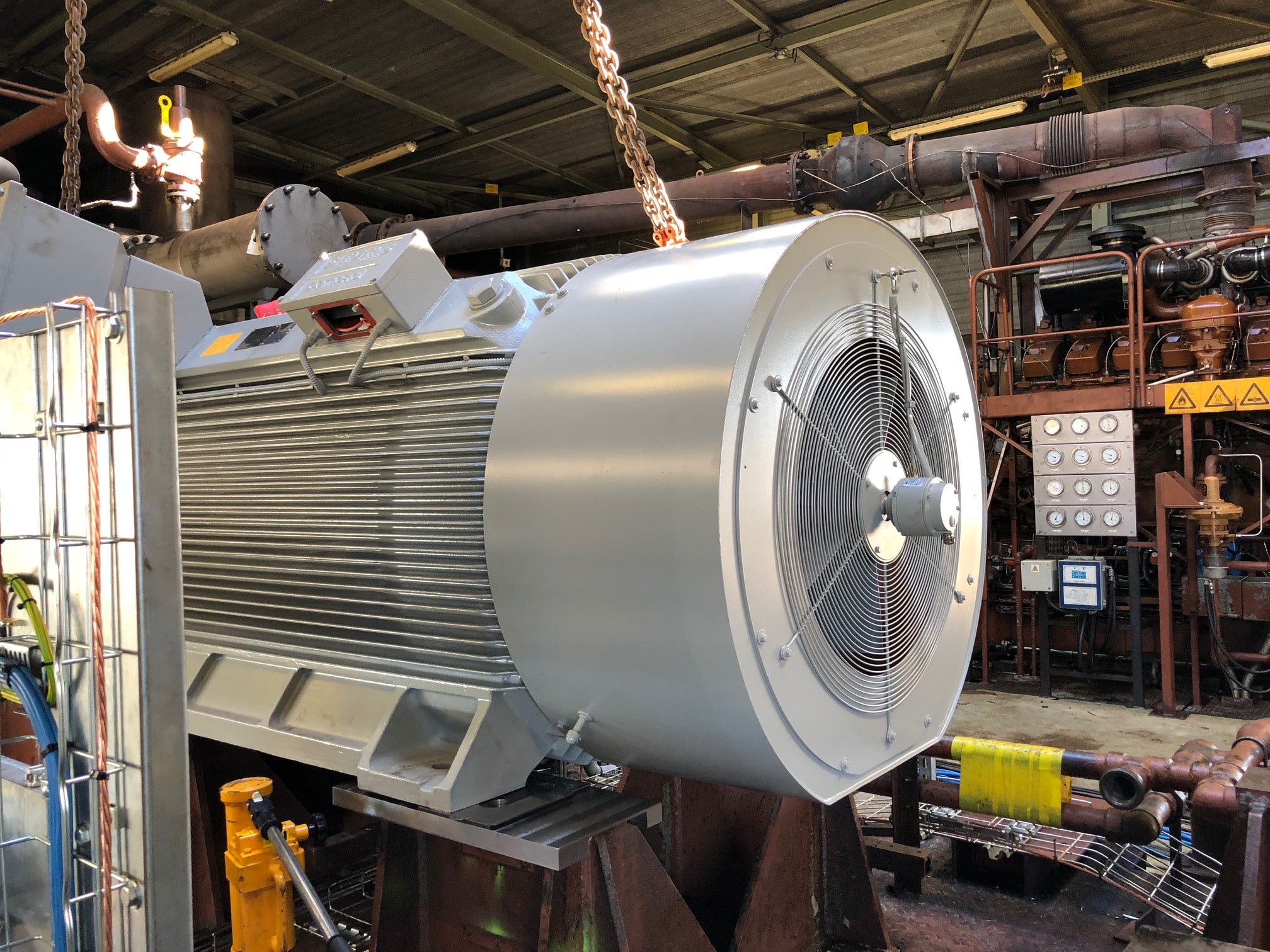

Drive

- Sizing drive motor torque

- DC Bus architecture, AFE power supply, network reinjection

- Drive Control Chart (DCC) Programming; Extended safety functions (STO, SS1, SLS, SLP etc.)

Motion

- Multiple axis management: positioning, synchronism, electronic reducer, cam profile

and trajectory interpolation - Line regulation (rolling, unrolling, S-block, on-the-fly cutting, batteries, loop pit, fast advance, sequenced, stagnation etc.)

Automation

- Project management and document system.

- Method: Operating specification, organic specification, architecture and safety, programming, test protocol, test platform book and record, simulation, static and dynamic reception, implementation and optimisation, remote control etc.

Digital control (DC)

- Machine tools retrofit: milling machine, grinding machine, boring tool, lathe

- Toolshop management

- Spare parts programme

- Compliance and safety

Robotics

- Key-in-hand integration of robotic islands: Handling/assembly, vision monitoring etc.

- Environment, location, risk

- 3D mechanical planning and design: Catia, Solidworks etc.

- Feasibility, trajectory simulation, cycle time: ProcessSimulate, RobotGuide etc.

- Platform, trial assembly

- Implementation and training

Engineering

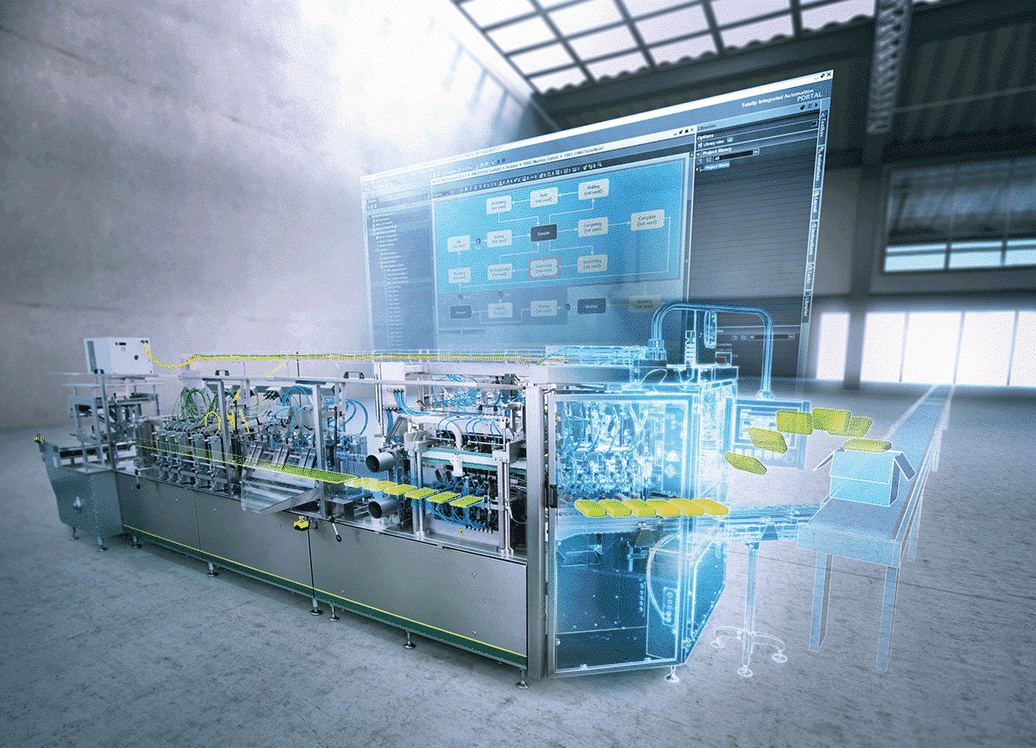

Digital Engineering

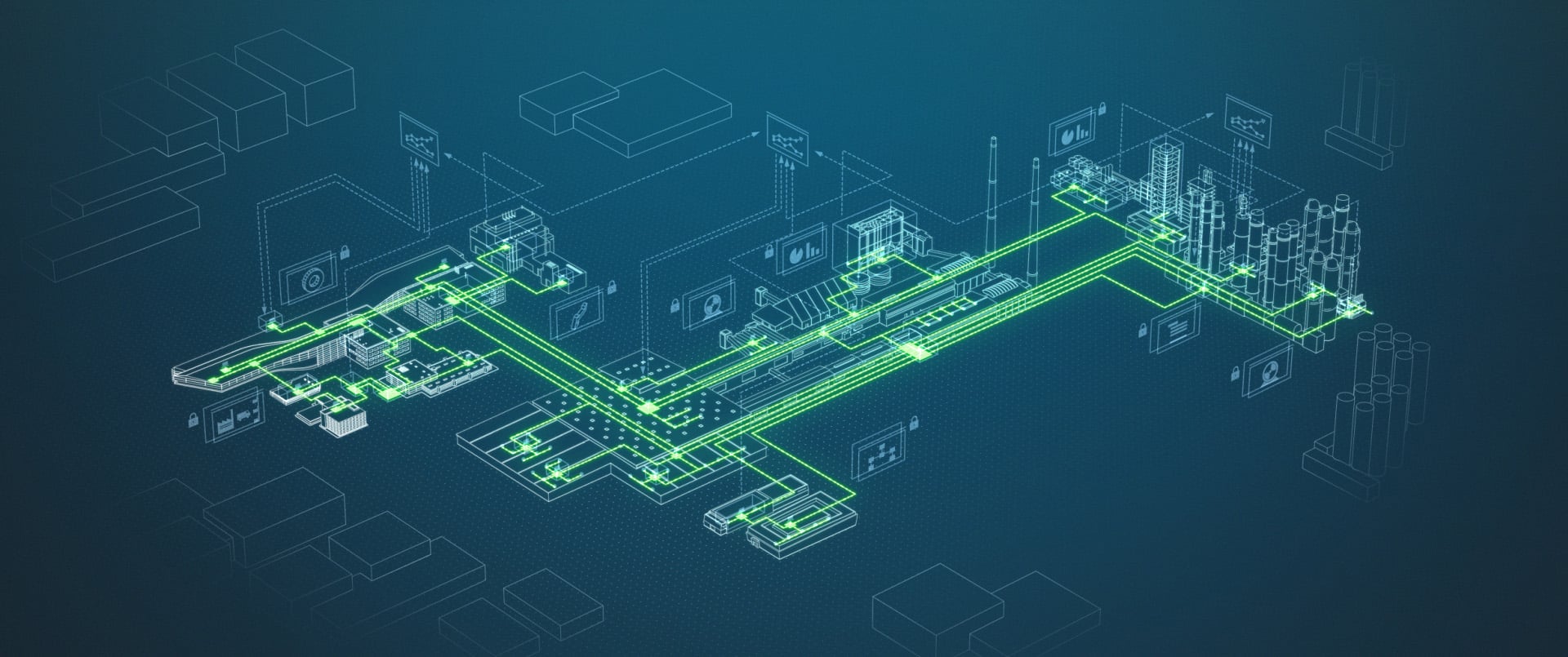

Today, we are evolving towards 4.0 integration by supporting our clients on the challenges of digital transformation in factories, on existing lines and machines. With our SMART environment ![]() , we can work towards operations which guarantee production, while limiting machine wear and tear and energy consumption.

, we can work towards operations which guarantee production, while limiting machine wear and tear and energy consumption.

SMART

SMART are DV GROUP’s innovative solutions for better management of productivity, energy, maintenance and quality at your industrial sites. They combine advice, support and monitoring solutions to identify, analyse and make your data speak for itself.

-

SMART TECHNIC : Operational optimisation of your installation

Our vertical system analyses process/maintenance data in real time, and combined with our expertise in drive systems (motor and drive maintenance, etc.), enables you to increase machine availability, anticipate stock management and migrate to condition-based or predictive maintenance.

-

SMART ENERGY : Reducing energy bills and environmental impact

SMART ENERGY is software solution which will allow you to have a complete view of your site’s energy consumption. You can monitor your consumption of:

- Electricity, gas, water, temperature, air and the quality of your network.

Digital twins

Simulate your production tool:

- Test a new production before implementation

- Optimise productivity

- Introduce a new resource while providing security for your investment

- 3D feasibility study for consultation

- Help in decision-making and guidance in choosing people, involving a much greater man-machine collaboration than before.

- Increased security

3-D installation: positioning data of different types and sources; Equipment simulation: the various types of simulation ; Flow simulation: after having carried out an empty simulation, it is possible to load production weights and flows.

Flow simulation

- Visualisation and understanding of flows

- Identification of opportunities for improvement: Identification of adjustments to be made in order to optimise work flows and improve efficiency (bottlenecks, waiting times etc.)

- Implementation and feedback: performance measurements etc.

Engineering

Design

Feasibility study

CDC development and drafting

Architecture and scaling

Functional analysis

Risk analysis

Technical documentation

Engineering

Associated services

We develop contractual solutions adapted to your individual processes and your organisations, built in collaboration with the Technical, Production and Purchasing departments. We respond accurately to your challenges, through our commitment to availability with our SUPPORT, productivity with our equipment / PDR service and guarantee the development and performance of your equipment giving you long-term peace of mind.

Equipment / PDR

New and reconditioned products.

Support

Our experts are here to listen to you and provide technical support.

CEE EDF

As partners of EDF, we can help you put together your grant applications.